-

Products

-

Lab Instruments

Titration Systems Beverage Analysers

-

Lab Meters and Probes

Calibration Standards Sension+ Meters and Probes

- Chemistries, Reagents, and Standards

-

Online Analysers

Ammonium Analysers Chlorine DioxideChlorine Analyzers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analogue)

- SC4500

- Orbisphere 366x Ex

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Orbisphere 51x Hydrogen

pH & ORP Sensors- 1200-S ORP

- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP pH

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

-

Automated Lab Systems

Automatic Laboratory Analyser

- Samplers

- Test Kits & Strips

-

Microbiology

Prepared MediaKits Labware

- Accessories

- Funnels, Pumps & Manifolds

- Microbiology Filters

- Petri Dishes & Accessories

- Sampling Bags

- Vials, Tubes, Bottles & Racks

-

Lab Equipment and Supply

General Lab Consumables Books and Reference MaterialGlassware/Plasticware InstrumentsSafety Equipment Apparatus

- Claros Water Intelligence System

- Electrochemistry

-

Lab Instruments

- Parameters

- Industries

- Brands

- Service

- Support

- News & Events

Analytics solutions for the Paper Industry

Giving you confidence for the tough decisions

All industries have common goals: high quality products that meet customer needs, and process efficiency. Using the right analytics solution can help ensure product quality and optimize production processes; it can also support water conservation, environmental profile improvements and regulatory compliance.

Every day choices are made on product release, process adjustments or responses to new issues. When making important decisions you need to be confident in the data available, so when looking for an analytics solution chose one that gives you confidence for the tough decisions.

All industries have common goals: high quality products that meet customer needs, and process efficiency. Using the right analytics solution can help ensure product quality and optimize production processes; it can also support water conservation, environmental profile improvements and regulatory compliance.

Every day choices are made on product release, process adjustments or responses to new issues. When making important decisions you need to be confident in the data available, so when looking for an analytics solution chose one that gives you confidence for the tough decisions.

![]() Chlorine total, free: Process efficiency, control biocide dosing and cost.

Chlorine total, free: Process efficiency, control biocide dosing and cost.

![]() Conductivity: Quality control, simple check on incoming water quality.

Conductivity: Quality control, simple check on incoming water quality.

![]() Hardness: Production performance, check impact on pre-treatment costs or potential for in-plant scale/deposits.

Hardness: Production performance, check impact on pre-treatment costs or potential for in-plant scale/deposits.

![]() pH value:Plant life/efficiency, check potential for in-plant corrosion.>

pH value:Plant life/efficiency, check potential for in-plant corrosion.>

![]() TOC: Production performance, check potential for non-ionic inorganics to cause deposits.

TOC: Production performance, check potential for non-ionic inorganics to cause deposits.

![]() Turbidity: Quality control, check effectiveness of filtration and microbiological quality.

Turbidity: Quality control, check effectiveness of filtration and microbiological quality.

![]() Hydrazine: Monitoring avaids overdosing of oxygen scavengers.

Hydrazine: Monitoring avaids overdosing of oxygen scavengers.

![]() Oxygen: Plant life/efficiency, control oxygen scavenger dosing that reduces corrosion.

Oxygen: Plant life/efficiency, control oxygen scavenger dosing that reduces corrosion.

![]() Phosphate: Plant life/efficiency, control phosphate addition that reduces corrosion and deposits.

Phosphate: Plant life/efficiency, control phosphate addition that reduces corrosion and deposits.

![]() Silica: Silica precipitates damage to turbines and tubes.

Silica: Silica precipitates damage to turbines and tubes.

![]() Sodium: Plant life/efficiency, an indicator of efficiency loss in ion exchangers or membrane systems used for pre-treatment.

Sodium: Plant life/efficiency, an indicator of efficiency loss in ion exchangers or membrane systems used for pre-treatment.

Quality control, to ensure optimum concentration of additives and fillers to meet quality requirements regarding e.g. strength, whiteness, opacity, restistance to grease and yellowing :

Oxygen

Oxygen Starch

Starch Sulphate

Sulphate

COD/TOC

COD/TOC Conductivity

Conductivity Hardness

Hardness

![]() Solids: Production performance, prevent the screen from being plugged.

Solids: Production performance, prevent the screen from being plugged.

![]() pH value: Plant life/efficiency, monitor white water quality to improve flocculation and reduce production costs.

pH value: Plant life/efficiency, monitor white water quality to improve flocculation and reduce production costs.

![]() AOX: Regulatory compliance, monitor concentration of organic halogenides in discharged water.

AOX: Regulatory compliance, monitor concentration of organic halogenides in discharged water.

Quality control, to ensure optimum concentration of additives and fillers to meet quality requirements regarding e.g. strength, whiteness, opacity, restistance to grease and yellowing

Oxygen

Oxygen Starch

Starch Sulphate

Sulphate

COD/TOC

COD/TOC Conductivity

Conductivity Hardness

Hardness

![]() Solids: Production performance, prevent the screen from being plugged.

Solids: Production performance, prevent the screen from being plugged.

![]() pH value: Plant life/efficiency, monitor white water quality to improve flocculation and reduce production costs

pH value: Plant life/efficiency, monitor white water quality to improve flocculation and reduce production costs

![]() AOX: Regulatory compliance, monitor concentration of organic halogenides in discharged water.

AOX: Regulatory compliance, monitor concentration of organic halogenides in discharged water.

Request more info

Downloads

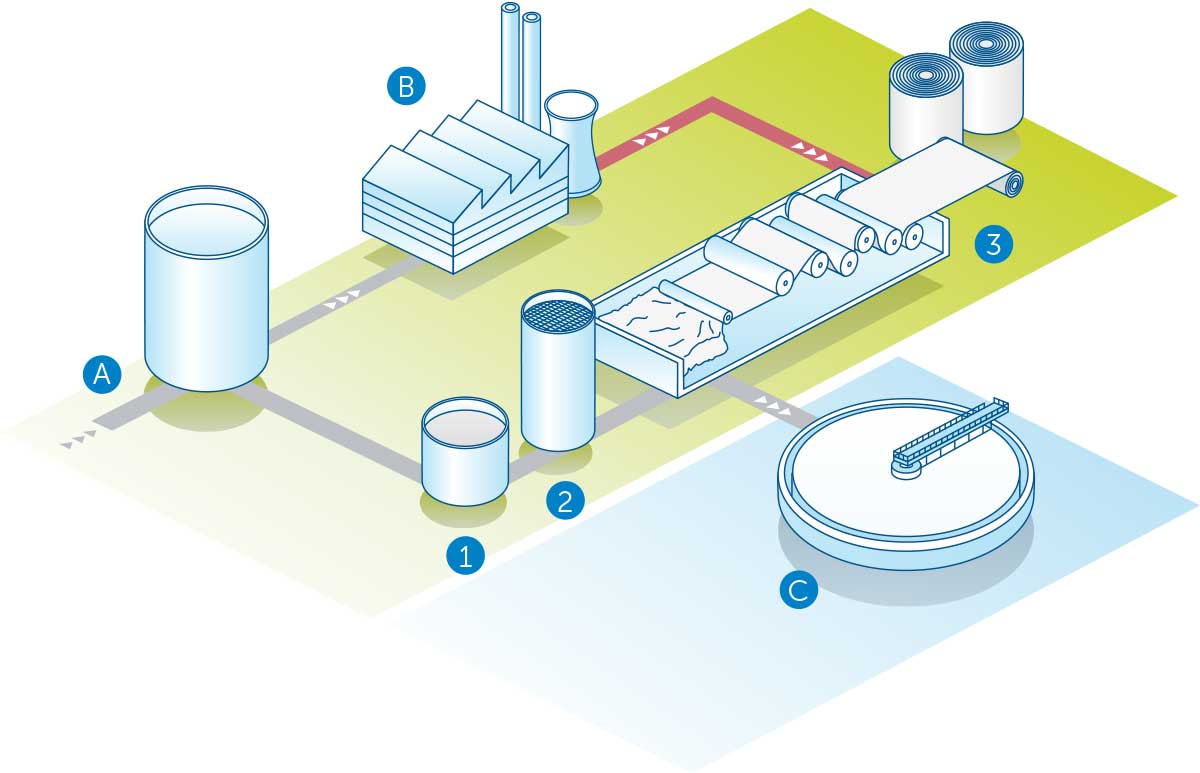

Where, why, what and how to analyse

Optimisation of biological treatment plant in the Pulp and Paper Industry

Advanced online instrumentation helps DAF systems lower costs

HACH LCK CUVETTE TEST SYSTEM

HACH CHEMISTRIES, REAGENTS AND STANDARDS

LCK Cuvette Tests: Insert, Read, Finish Approved Hach

Cleaning and maintenance of pH probes