Measurement to Maximize Production

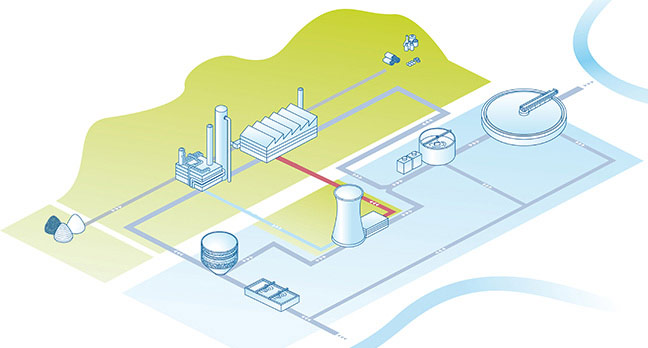

The Hach® analytics portfolio for manufacturing is designed to give you the accurate, reliable and informative data you rely on to confidently navigate the tough decisions on product release, process adjustments and response to regulatory changes. With Hach as your partner in process monitoring and laboratory analysis, you can more effectively control product quality, control oxygen scavenger dosing, control corrosion and deposits—and therefore control costs.

From a simple, dedicated meter to on-line measurement or wastewater treatment optimization, our solutions are based on years of innovation and a desire to provide the simplest way to results you can trust.

Our products, application support and local service help you:

• Maintain quality by ensuring consistent finished products that meet customer needs

• Maximize uptime of equipment and production

• Maintain regulatory compliance, environmental profile improvements and water conservation

• Monitor efficiency loss

• Protect your investment via process efficiency and prolonged plant and equipment life

Providing solutions for:

• Biotech process industry

• Flexible production

• Pharmaceutical technology

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.

Online Support

Hach Support Online (HSO) pools more than 70 years of water analysis knowledge into a powerful global community. Flowing directly into our customer and technical support teams, this dynamic resource delivers real-time answers, user-friendly search tools, multiple types of content, and easy ways to connect with Hach experts. With HSO, you get the information you need and together, we can ensure water quality for people around the world.

Technical Training

Hach Training Center provides relevant, hands-on training to your team, giving them the experience they need to master various theories and techniques—and produce results you can trust for quality assurance, environmental safety, and regulatory compliance. Hach experts offer a large course catalog of workshop training, personalized training, and digital learning designed to increase proficiency and confidence for plant operators, instrument and field technicians, laboratory personnel, and plant managers and superintendents.

Service

Hach ServicePlus ® Programs have been developed to help solve your maintenance and support problems. Whether it’s a lack of resources or skills, an instrument that is down, compliance concerns or the need for a predictable budget, we have programs to fit the unique challenges you face in your organization.